LEV Testing

What we do

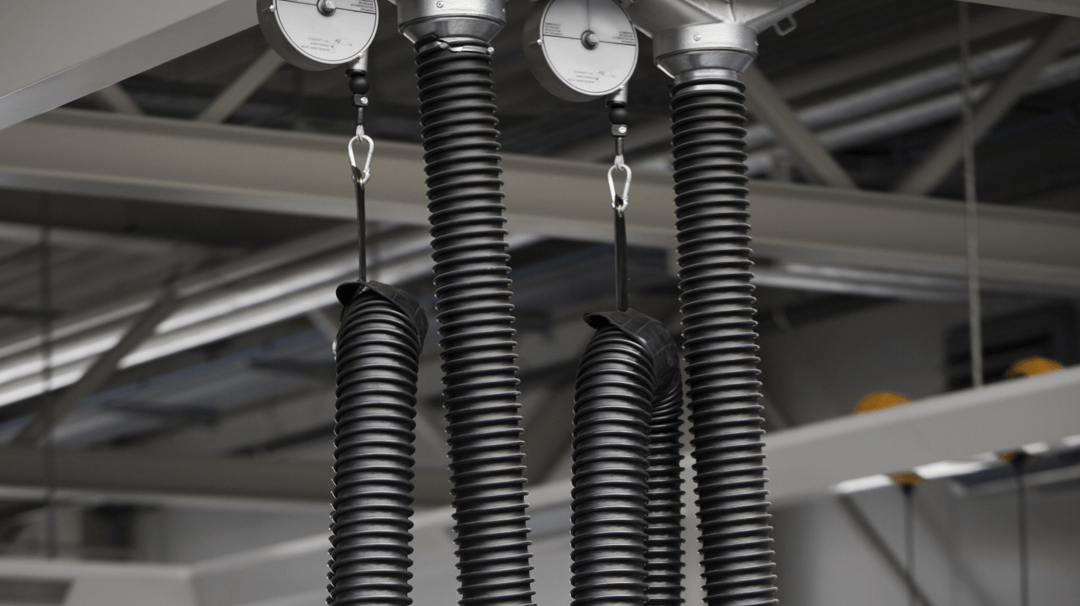

We evaluate all types of LEV systems, including fixed and mobile extraction units, on-tool capture systems, booths, enclosures, and ducted installations. Each assessment includes thorough examination and testing using HSE-approved methods to ensure system performance and compliance.

Our consultants check airflow rates, static pressure, filter conditions, and overall capture efficiency. Every component is inspected, including hoods, ducts, filters, fans, and discharge points, to identify wear, inefficiency, or blockages.

We work with a broad range of sectors, including manufacturing, food processing, and laboratories. Our team assesses LEV systems used in processes like welding, grinding, paint spraying, and chemical handling. We tailor our approach to suit the specific contaminant type and exposure risk, and support single-site operations as well as multi-system industrial sites with complex extraction needs.

Why it matters

All assessments are conducted in accordance with COSHH Regulation 9, which mandates regular inspection (at least every 14 months), and HSG258 guidance, which defines how testing should be conducted, along with best practice in LEV system design and maintenance. We help ensure your systems remain compliant, effective, and fit for protecting the breathing air of your employees.

Validate Consulting is proud to cover everything from initial assessments and routine re-inspections to post-installation validation and system commissioning. Beyond basic compliance, we assess how efficiently your LEV systems protect workers. We identify where systems may be underperforming or at risk of failure, highlighting issues that could compromise health or cause operational downtime.

All assessments are carried out by our expertly trained Occupational Hygiene Consultants (with a minimum of BOHS P601) with experience across multiple industries. All of our equipment used in testing is annually calibrated. We operate throughout the UK, offering both local and nationwide coverage.

What you receive

Each assessment results in a detailed report summarising test results, system performance, maintenance needs, and any non-compliance findings. Reports include system specific details, and recommendations for improving protection and health of workers.

Get in touch

Whether you're looking to meet legal obligations or proactively protect your workforce, we're here to help.

Get in touch to discuss your needs or request a quote.

LEV FAQ’s

How often am I required to test my LEV?

HSG 258 stipulates that systems must be checked every 14 months with some systems requiring more frequent testing depending on the processes:

- Jute cloth manufacture – 1 Month

- Processes in which blasting is carried out or incidental to the cleaning of metal castings, in connection with their manufacture – 1 Month

- Processes, other than wet processes, in which metal articles (other than of gold, platinum or iridium) are ground, abraded or polished using mechanical power, in any room for more than 12 hours in any week – 6 Monthly

- Processes giving off dust/fume in which nonferrous metal castings are produced – 6 Monthly

What is COSHH Regulation 9?

- Every employer who provides any LEV to meet regulation 7 shall ensure that, it is maintained in an efficient state, in efficient working order, in good repair and in a clean condition. – COSHH Regulation 9.1.

- When engineered controls have been used the employer must also make sure that the controls are thoroughly inspected and tested with a record that is kept for a minimum of 5 years. The Regulation also states:

- Any LEV system must be thoroughly appraised and tested at least once every 14 months. This is reduced to 6 months in certain circumstances. – COSHH Regulation 9.2.

What Our Clients Say

Why choose Validate Consulting

- Trusted Through Word-of-Mouth

- Most of our business comes from client referrals, a true testament to the trust, reliability, and satisfaction we deliver.

- Tailored, Practical Solutions

- We don’t believe in one-size-fits-all. Every recommendation is tailored, realistic, and grounded in your specific operational needs.

- Expertise Without the Ego

- Our experienced consultants are highly qualified and technically sound, but we’re easy to work with, friendly, and down-to-earth.

- Fast Turnaround, Without Cutting Corners

- We deliver high-quality reports and results promptly, helping you make quick, informed decisions without delay.

- Clear Communication, No Jargon

- We explain risks and controls in plain language, so everyone from operators to directors understands what needs to be done and why.

- Independent and Unbiased Advice

- As an independent consultancy, we’re not tied to equipment sales or external agendas, just your best interests.

- Specialists in the Realities of Small and Medium-Sized Businesses

- We understand the challenges SMEs face and work within your budget, timeframes, and operational constraints.

- Building Long-Term Relationships, Not Just Jobs

- We aim to become your trusted long-term partner in health protection - not just a one-off service provider.